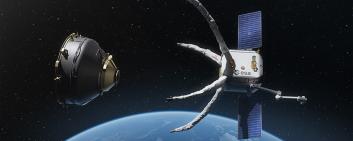

Maxon's motors developed such a reputation for reliability that the engineers of the first Mars Rover used 11 maxon motors for the Sojourner. As Roger Villiger, Head of the Aerospace Business Unit at maxon, explains, since participating in the first NASA mission, the company has supplied motors for the majority of Mars missions, including those yet to be launched and the first drone mission. For the latter, maxon provided the compact drives needed to adjust the pitch of the rotor blades.

The question arises: why is maxon, which has achieved global stature, still headquartered in a picturesque Swiss village? The answer lies in maxon's commitment to its roots. The company has been headquartered in Sachseln, Obwalden, Switzerland — its birthplace — for more than six decades. This may explain why Swiss principles of quality and reliability remain central to maxon's ethos, even as it expands its global presence.

Roger Villiger explained that most innovation projects, such as the drone solutions, involve input from maxon's international R&D teams. He explained: "Despite our global reach, our headquarters remains the most important hub for the drone industry due to its proximity to the Swiss Drone Valley and the access it provides to specialists and infrastructure."

Maxon's commitment to quality is demonstrated not only by its actions, but also by its achievement of five internationally recognised certifications: ISO 9001, ISO 14001, ISO 13485, EN 9100 and IATF 16949. Each certification is a testament to maxon's high standards in areas such as medical and aerospace. The rigorous testing required for these certifications allows maxon to demonstrate its unwavering commitment to quality - a commitment summed up in its motto "Quality without compromise", which is prominently displayed on its website.

Roman Meier, Technical Project Manager in the Aerospace Business Unit, explains that this commitment to quality results in a longer product life cycle. Customers appreciate maxon's robust, rigid product designs that can withstand the harsh conditions often encountered by drones, such as rain, snow and wind. The efficiency-optimised drive systems developed by maxon mean that drones need to be recharged less frequently, enabling long-distance applications with fewer charging stations in between. According to Roman, the longevity and durability of maxon's products make them more cost-effective in the long run than alternative options.

Despite our global reach, our headquarters remains the most important hub for the drone industry due to its proximity to the Swiss Drone Valley and the access it provides to specialists and infrastructure.

Entrance into the global drone market

For those still unfamiliar with maxon, this manufacturing giant is best known for its motors, which are often showcased and promoted at a variety of international events. Mountain bike enthusiasts may be more familiar with the company's recent foray into the e-bike sector with its maxon BIKEDRIVE AIR product. Maxon's presence also extends beyond just these markets, with a wide range of industries and companies worldwide using its products, a fact reflected in the size of its team of over 3,000 people spread across 40 locations worldwide.

The move into the drone sector came about when maxon's management identified compatibility between its lightweight motors and emerging mobility solutions such as e-bikes and drones. The need was clear: these solutions required a safe, reliable, efficient and lightweight design.

Around 2015, maxon started receiving enquiries from emerging customers in the drone industry who had recognised the potential of their lightweight motors. These drone companies expected maxon's products to be adaptable to their needs, given the lack of alternatives on the market at the time. Initially, maxon was not equipped to meet these demands, so it laid the groundwork for the future by embarking on a research and development project aimed at developing drone motors to meet these emerging needs.

Fostering cooperation with Swiss drone businesses

Switzerland's reputation for providing the best conditions for the development and operation of drones is well-established in the aviation sector. As a result, renowned organisations such as Auterion, Jedsy, RigiTech and Flybotix have chosen to establish their headquarters in the country. The maxon Group is capitalising on this robust network by partnering with these drone companies that are involved in complex product development. This allows for a smoother technical development of the drones, supported by maxon's team of experts.

The drones that emerge from these collaborations embody the unique competencies of each company involved, increasing efficiency and compatibility with different software interfaces. During our interaction, maxon's Roman Meier showed us a test drone that incorporated motors and motor control electronics developed by maxon, while other aspects of its construction used elements from Auterion or standard carbon fibre materials to maintain structural integrity. The collaboration between maxon and Auterion has led to the optimisation of product interfaces, strengthening their partnership in this innovative market.

Roman emphasised that these collaborations allow each company to leverage its strengths to create the best overall product. This is in contrast to the modus operandi of many other drone companies, which aspire to be full end-to-end manufacturers of all components, a goal that is currently unattainable due to the nascent state of the industry and lack of practical experience.

Shaping the future of the drone industry

As the aerospace sector continues to evolve, drones, or UAVs, will play an increasingly important role, impacting a wide range of sectors from consumer goods to agriculture and even security. In anticipation of this growing demand for safe, reliable and durable UAVs, maxon launched a project in 2019 aimed at developing drone motors and controllers.

This project presented a unique set of challenges and required a steep learning curve. Through extensive testing, the team discovered the crucial role of cooling systems for these motors, leading to the design of motors with efficient internal cooling systems. Other considerations, such as sophisticated motor control algorithms and the effect of gyroscopic forces, were found to have a significant impact on UAV motors. This has led to the development of specialised test equipment tailored to these scenarios.

Extensive efficiency testing was carried out to improve the performance of UAV propulsion systems. Collaboration with various market players further deepened maxon's understanding and expertise in many areas, underlining the importance of a comprehensive approach to building reliable drones. The maxon team, spanning different departments and industries, worked together to create the ideal motor for each customer. This collaborative effort was met with overwhelmingly positive feedback, particularly regarding the longevity of the newly developed lightweight drone motors and electronic speed controllers.

With the dawn of each new day, new customer projects are being developed, signalling the imminent introduction of innovative motors and control electronics for widespread use in the drone industry.