Researchers from the Swiss Federal Laboratories for Materials Science and Technology (Empa) have developed an innovative form of plastic. The epoxy resin they created can both be repaired and recycled. According to a press release, this is a first. Before now, it has not been possible to recycle epoxy resins. This is because the polymer chains are closely crosslinked in this type of plastic, meaning that it is impossible to melt them. “Once they have reached the end of their service life, they are incinerated or disposed of in landfills”, as Wenyu Wu Klingler from the Advanced Fibers lab of Empa in St.Gallen explains in the press release.

However, epoxy resins boast excellent mechanical and thermal properties, as Empa writes in the press release. Accordingly, they are used in a variety of industrial applications - for example to manufacture components used in airplanes, cars, trains, ships and wind turbines.

The special epoxy resin developed at Empa should therefore, among other aspects, help to make the use of fiber-reinforced polymers more sustainable for industrial applications. “The production of carbon fibers requires a lot of energy and releases an enormous amount of CO2”, comments Sabyasachi Gaan from the Advanced Fibers lab at Empa. If carbon fibers could be returned to the materials cycle once they have been used, this would improve their environmental footprint and help to reduce the price, Gaan explains further.

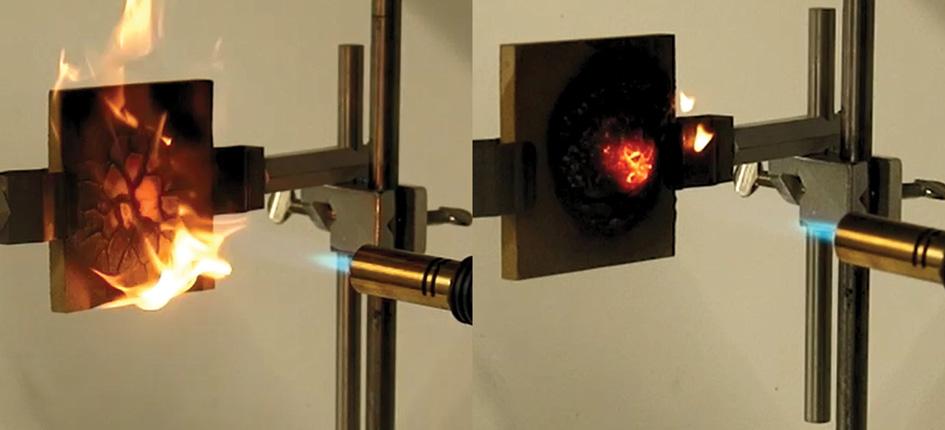

According to Empa, fiber-reinforced polymers, such as those used in the construction of airplanes, trains, boats, cars and bicycles, are not the only potential areas of application for its innovative plastic. For example, the epoxy resin could also be used as a coating for wood floorings in the form of a transparent, durable layer that offers reliable flame-retardant properties.